EXHIBITS AND ARTEFACTS

There is a 28 page Information Booklet available at the entrance, this is included in the admission price, plus we have helpful volunteers who are happy to expand on the information. To view everything properly and enjoy a casual stroll around the surrounding grounds you will need at least an hour.

Demonstrations on the machinery working are usually held on Friday Morning but can be arranged at other times for group bookings.

Hargan’s Mobile Buzz Saw

Only a few of today’s retired timber workers would remember how the industry was revolutionised in the late 1930’s by the introduction of the Hargan Mobile Buzz Saw. Originally designed by Donald Edward Hargan, this particular saw was restored by Will Johns, a Museum volunteer.

The idea of this saw when first engineered was to build a machine rugged in construction but light and mobile enough to enable the operator to fell and cut the maximum amount of timber with the least effort and at the lowest cost. Needless to say, this was an extremely dangerous machine to operate.

619 year old Kauri Pine Disc

This Kauri Pine was logged in North Queensland in 1939. It measures a massive 2.59 metres in diameter. A cross section of the trunk has been put to ingenious use as an historical chart. Momentous world events over the past six centuries are plotted on the tree’s growth rings.

Alongside the disc is a section of Kauri Pine. This section of timber, measuring 2.4m by 1.2m by 10cm thick, was milled at Tolga Sawmill on the Atherton Tablelands. This piece and the adjoining disc were cut from the same large Kauri Pine logged at Danbulla State Forest.

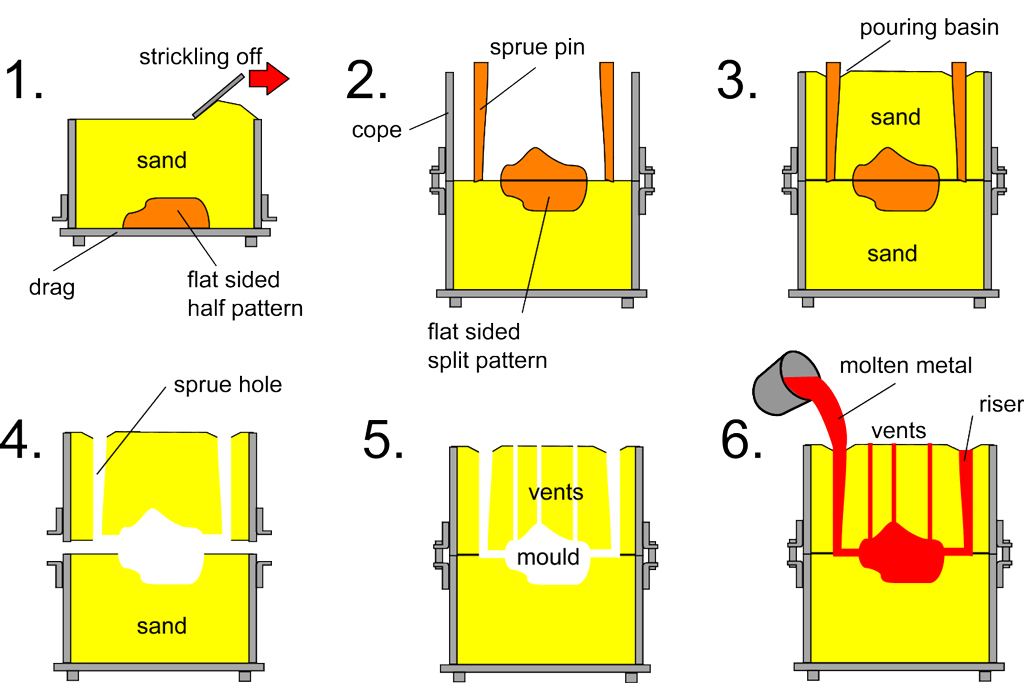

SAND CASTING

Sand casting, also known as sand moulded casting, is a metal casting process characterised by using sand as the mould material. The term “sand casting” can also refer to an object produced via the sand-casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process.

The sand casting process involves the use of a furnace, metal, pattern, and sand mould. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mould, which is formed by the pattern. The sand mould separates along a parting line and the solidified casting can be removed. The steps in this process are described in greater detail in the next section.

Moulds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for moulding. The sand is typically contained in a system of frames or mould boxes known as a flask.

WOODWORKS MUSEUM

8 FRASER ROAD, GYMPIE QLD 4570

07 5483 6535

Email: woodworkmuseum@pfsq.org.au

OPENING HOURS

MONDAY – FRIDAY: 10AM – 3PM

CLOSED SATURDAY & SUNDAY

CLOSED PUBLIC HOLIDAYS

CLOSED EASTER WEEKEND

ENTRY FEES

$10 PER PERSON

CHILDREN UNDER 5 FREE